The primary objective of this project has been to characterize and monitor the injection of ~1 million metric tons (tonnes) of

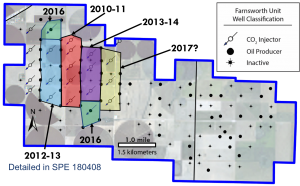

Farnsworth Oil Field showing existing wells and development plans. The phase III project has focused on the west side of the field which the operator believed was more amenable to the CO2 EOR project.

CO2 at Farnsworth Oil Field. At the proposed injection rate of 10 MMscf/d (~190,000 tonnes/yr), it will take approximately five years and four months to inject 1 million tonnes of CO2 into the target formation, the deep oil-bearing Morrow Formation in the FWU Area. All of the CO2 used at FWU is produced as a byproduct of industrial processes from nearby ethanol and fertilizer plants.

Chaparral LLC, the current field operator, is responsible for maintaining injection at the site, with its primary objective of optimizing the enhanced oil recovery effort. Chaparral has also helped SWP by facilitating the reservoir characterization, associated storage capacity evaluation and assessment of CO2 monitoring efficacy. SWP is also evaluating portability of results, and specifically applicability (transferability) of results with respect to other EOR fields. The FWU site is a unique opportunity for SWP to improve monitoring, verification and accounting (MVA) techniques during the project.

A variety of characterization, monitoring, and verification techniques have been used at FWU. Three wells have been drilled and cored in support of the characterization work. Seismic methods are emphasized, including 3D surface surveys (3D), 3D vertical seismic profiling (3D-VSP), and cross-well tomography (cross-well); passive seismic methods have also been employed to identify the size of the CO2 plume but have proven to be problematic in this area for a variety of reasons. Engineering and geochemical techniques such as analysis of injection rates, production well rates, as well as direct sampling of water, oil, and gas, use of introduced and/or natural tracers, groundwater chemistry monitoring, downhole pressure and temperature monitoring at injectors (at the surface) and production well locations (at the surface for flowing wells and downhole where applicable with electrical submersible pumps so equipped), soil gas sampling, and other methods as found applicable will also be employed.